Unique Pile Anchor SOE System

The widening of the existing Long Island Railroad (LIRR) Atlantic 6 Bridge, which spans the Van Wyck Expressway and frontage roads, included new bridge abutments and a center pier. The widening was also performed very close to active LIRR tracks. The support of excavation (SOE) system in the contract documents included soldier piles with tiebacks. However, installing tiebacks would result in significant traffic delays along the high-volume frontage roads and some tiebacks could not be installed because of site constraints. GEODesign was retained by the contractor to design a system that eliminated the tiebacks.

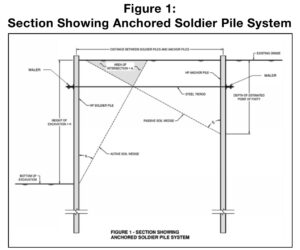

GEODesign and the pile driving contractor thought that a row of “deadman” anchor piles, located outside the active excavation zone, and connected to the soldier piles using high strength tie rods (see Figure 1 – click to enlarge) might be the answer. Since this system was unique, the main design challenge was to develop a reasonable approach to estimate the lateral capacity of the anchor piles.

Since the soil conditions included relatively dense sands and deep groundwater, it was believed that the lateral capacity of the anchor piles would be relatively high. The design was complicated by site constraints which required that the soldier piles and anchor piles be located closer to each other than desired, which resulted in the resisting soils of the anchor piles intersecting with the active soil zone of the soldier piles (see Figure 1 – click to enlarge). To account for this, the total passive resistance of the anchor piles was adjusted based on the ratio of the area of intersection to the total area of the passive wedge. Based on the design results, HP14x89 and HP14x117 piles were specified for the soldier and anchor piles.

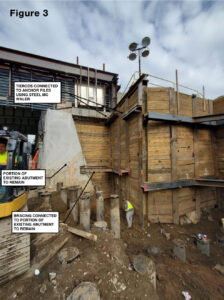

The construction procedure included driving the soldier piles and anchor piles, excavating between the soldier and anchor piles, and installing the walers and tie rods (see Figures 2 and 3 – click to enlarge). The tie rods were then pre-loaded by jacking, which was done to mobilize the anchor pile resistance so that lateral soldier pile deflections during further excavations would be reduced, which was important because of the proximity to the adjacent active railroad tracks.

The construction procedure included driving the soldier piles and anchor piles, excavating between the soldier and anchor piles, and installing the walers and tie rods (see Figures 2 and 3 – click to enlarge). The tie rods were then pre-loaded by jacking, which was done to mobilize the anchor pile resistance so that lateral soldier pile deflections during further excavations would be reduced, which was important because of the proximity to the adjacent active railroad tracks.

The east abutment SOE design and construction was particularly challenging because the excavation height was approximately 36 feet and it was very close to the active tracks. The analyses indicated that a single level lateral bracing system may result in relatively large soldier pile deflections, which could result in unacceptable track settlements. GEODesign designed a lower bracing system that was connected to the existing abutment to remain (see Figure 3 – click to enlarge).

During construction, it was also found that the distance from the existing east abutment to the SOE location was much greater than shown on the contract drawings, which would require a more substantial support system. This location was also extremely close to the active tracks. GEODesign acted quickly to provide the contractor with a bracing system (see Figure 4 – click to enlarge) that allowed the excavation to continue without delay.